What Is Cnc Turning – The Configuration Principles Of Cnc Turning

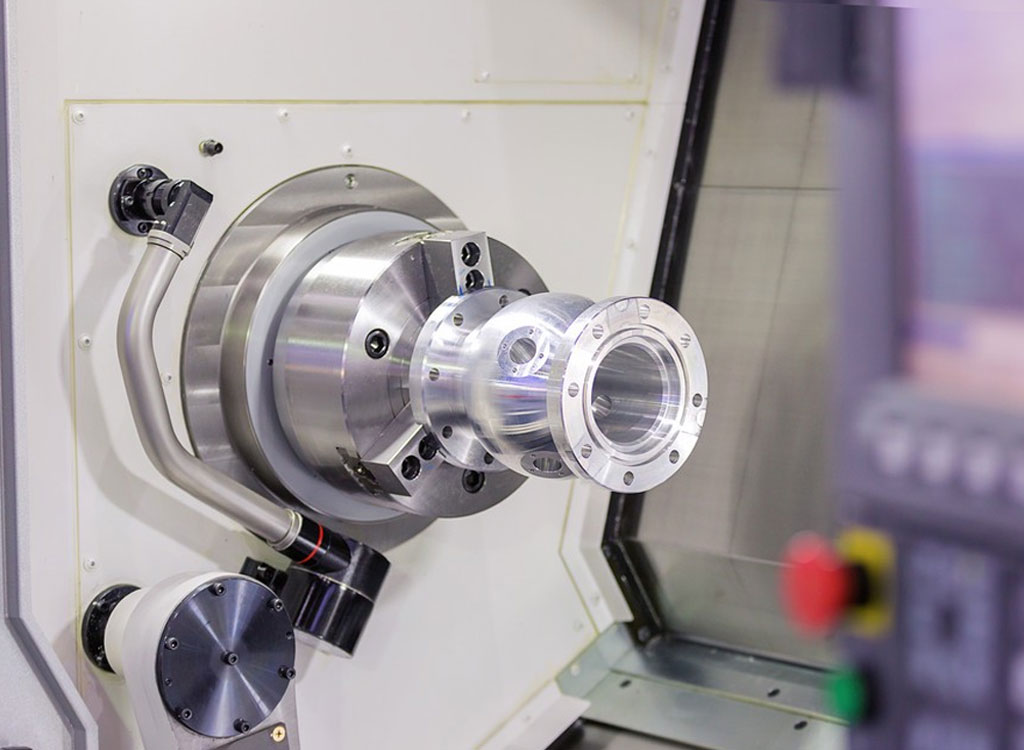

Cnc Turning Define

Turning is a cutting process in which the workpiece rotates and the turning tool moves in a straight line or a curve in the plane. Turning is generally carried out on a lathe to process the inner and outer cylindrical surfaces, end surfaces, conical surfaces, forming surfaces and threads of the workpiece.The automatic programming program and the tools used for machining are the two direct factors that affect the quality of CNC machining. The quality of the automatic programming program will directly affect the machining quality, production efficiency and product cost of the parts. During the programming process, the process formulation of the parts It plays a direct and decisive role in the setting and selection of related parameters. Parts Cnc Turning usually includes roughing, (semi-finishing), and finishing. Various processes and tool parameters need to be set in the automatic programming of CNC machining, such as: spindle speed S (dirty), feed speed ^ tool, tool movement, Cut deep, cut out, etc. Under the conditions allowed by the rigidity of the machine tool-workpiece-tool-fixture system, a larger cutting depth should be selected as much as possible to reduce the number of tool passes, shorten the Turning and auxiliary time, and improve production efficiency.

The blanks for turning should be drawn semi-finished products as much as possible, which can save the processing amount. The structure of other turning parts, such as thread, taper, knurling, arc, center hole, undercut, shoulder, etc., should also be made according to the standard value as much as possible. The configuration principles are:

1.The drawn smooth surface should not be processed as much as possible.

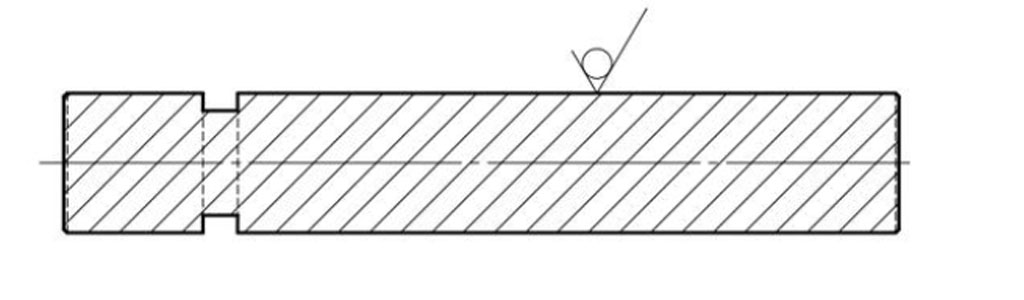

The drawn smooth bar can be used, and the smooth surface should not be turned into a step shape.

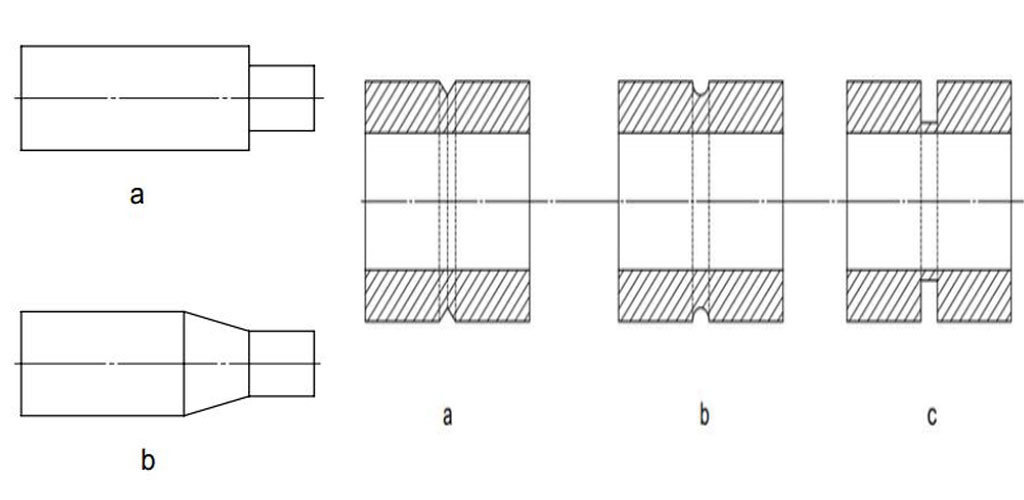

For example, when a shoulder with a large diameter needs to be turned on the shaft, a retaining ring or a pin ring can be used instead, or a small groove is turned on the shaft, and then a spring retaining ring is installed. This structure is also very suitable. As shown in Figure 1 below.

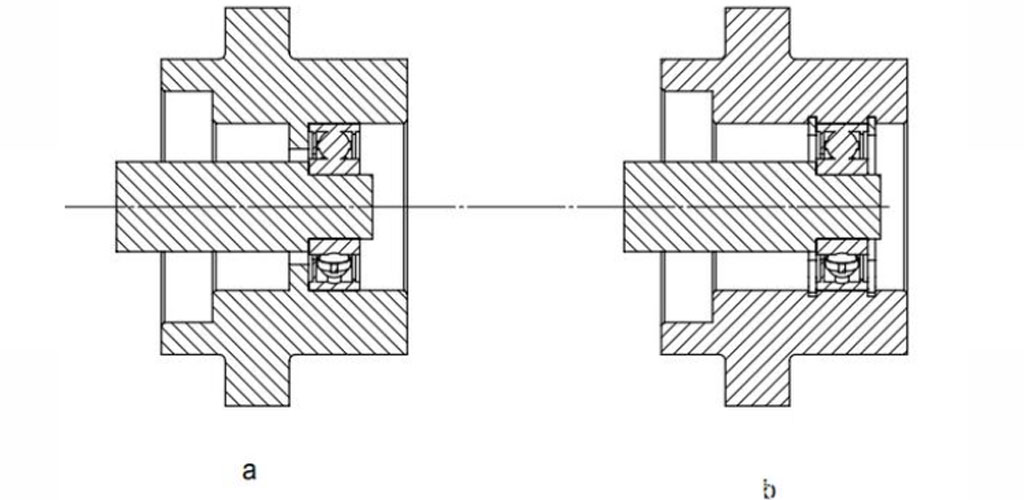

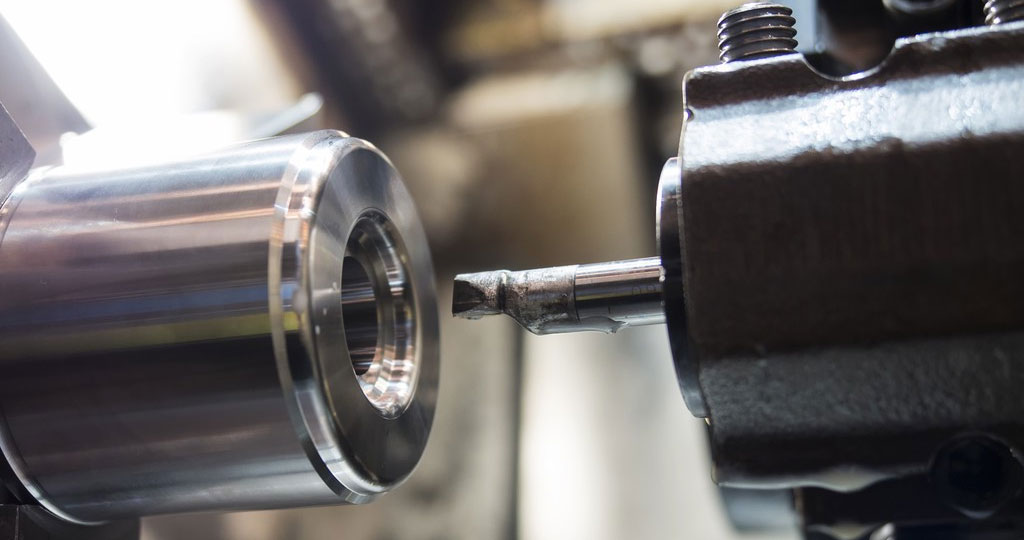

2.For stepped holes with coaxiality requirements, try to avoid changing the head and dig holes.

As shown in Figure a, the bearing seat holes have high coaxiality requirements.

At this time, it needs to be processed under one clamping to meet the requirements.

The configuration of the stepped hole as shown in Figure 2-a is difficult to process in one clamping.

If it is changed to the configuration shown in Figure b, there is no need to change the head for turning, and the hole can be ground.

3.Duplicate mating surfaces must be avoided. For reliable mating, there can only be one mating in the same direction.

Figure 3-a has too many fittings and is troublesome to process. If it is improved according to Figure 3-b, the cooperation is reliable and the processing is convenient. If it is changed to through straight holes, the hole shape is more suitable. As shown in Figure 3.

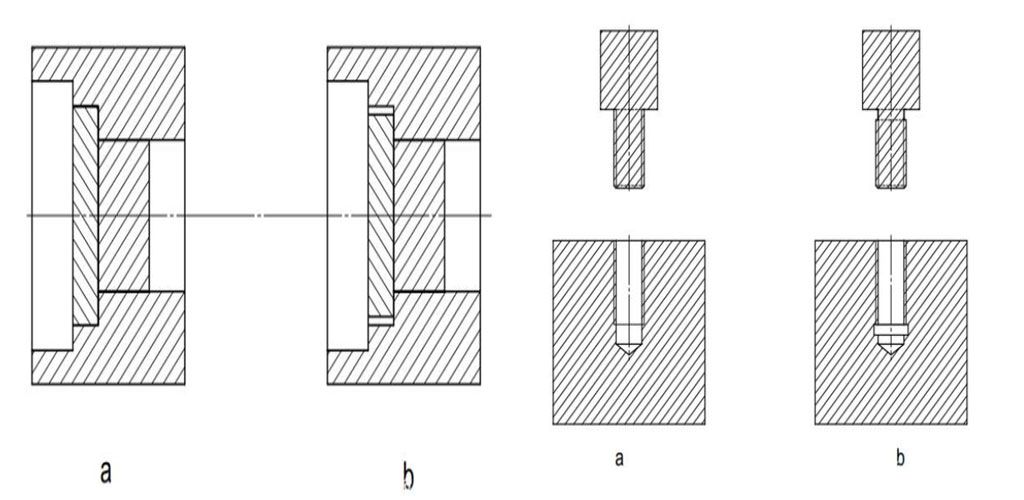

4.The tool outlet and related structures should be reserved for turning processing.

As shown in Figure a, the shaft and bushing need to be threaded. In order to ensure the effective length of the thread, the structure shown in the figure cannot be assembled in place. If a relief groove is pre-turned at the end of its thread, as shown in Figure b, the internal and external threads can be completely screwed together.

5.Change tools as little as possible to save man-hour consumption

When designing the stepped shaft, attention should be paid to the reasonable shape of the shaft shoulder. As shown in Figure a, the shaft shoulder is a plane transition, and it needs to be cut with two tools to form. If the shaft shoulder is designed as a tapered surface transition, only A tool is required to cut the jerk to form. Therefore, when the shaft shoulder is in special requirements, its shape should be determined as a tapered transition as well.

6.Avoid sharp joints and use grooved joints

Special attention should be paid to its strength. As shown in Figure 5-6, under fatigue stress, the pointed groove in Figure a is more prone to fatigue fracture than the circular groove in Figure b, and it is best to use rolling grooves. The deep groove in Fig. c is even more unsuitable, especially the deep groove in turning is easy to break due to stress concentration, so it should be avoided.

- Simplify the turning process as much as possible. Figure 7 shows a positioning screw device. If the configuration is as shown in Figure a, it is necessary to turn the shoulders at both ends, which is more labor-intensive. If it is changed to the configuration shown in Figure b, and the shaft is sleeved in the casing, the processing can be greatly simplified.

- Set enough clamping surfaces for parts processing. Use chucks and vices to clamp parts for processing. There must be enough clamping surfaces. Otherwise, reliable positioning and firm clamping cannot be guaranteed.

- Pay attention to the requirements of multi-tool turning on the structure of the part. Multi-tool turning has a direct relationship with the configuration of the part. If they are adapted to each other, multiple tools can be processed at the same time to improve efficiency. On the contrary, multiple cutters cannot work at the same time or there are idle paths, which wastes man-hours.

- Reduce the number of tool adjustments and replacements. On the same part, if there are multiple taper angles or rounded corners, if there are no special requirements, these taper angles or rounded corners should be made the same as possible, so as to avoid tool adjustment and rounding. Tool replacement.

- Minimize the finishing surface as much as possible. The smaller the finishing surface, the more cost-effective it is, and it is beneficial to hold high precision. Therefore, the shape of turning parts should take this principle into account.

- Try to use standard knives and reduce varieties. In mass production, using standard knives and reducing their varieties will not only facilitate production, but also save a lot of equipment costs. In order to use standard tools as much as possible, some unnecessary surface configurations should be changed to conical and cylindrical configurations as much as possible, so as to avoid the purchase of expensive special tools.

PTJ Hardware is a professional cnc turning parts manufacturer located in DongGuan, China since 2007. with ISO 9001 certification. We specialize in providing CNC turning, swiss turning, CNC machining, finish such as powder coating and assembly services for small or large volume lot sizes for a variety of markets. Whether the quantity is small or large, We has the capabilities of meeting our customers’most demanding needs.

CNC Turning: It is a process to manufacturing of high precision parts which required to be produced with high specifications. CNC turning works great when you have a small quantity requirement or 1000+ parts. CNC Turning Or Swiss Turning is widely used to machine engineering-grade plastic and metal parts to produce prototypes.

THE LEADING CHINA CNC TURNING SERVICES COMPANY

China is a top country when it comes to the CNC Turning services industry. Thus, PTJ Hardware can say that China CNC Turning services are the best in the world. The main reason for the popularity of Chinese CNC Turning services are;

Guarantee of low costs

and fast turnaround times

Our Cnc Turning Services Will Help In Making Your Projects Quick

Because of this, companies prefer to outsource their Turning needs from there. That is reality CNC Turning in China is an imperative step for many product developers. Because some other countries are like China in cost and performance.

It is well known that China can be difficult to navigate in CNC Turning. There are many CNC Turning companies in China, one of which is difficult to choose. And communications can be more imperative than domestic supply chains.

This article aims to make it easier for you to choose. You will get complete guidance about China CNC Turning services.The advantage of ptj cnc turning:

- Low, medium to high volume batches production run

- Rapid prototyping and end-use manufacturing

- High dimensional accuracy, high speed and high reliability

- A wide range of compatible metal and plastics materials

- Great productivity and improved efficiency

- Smooth finishes and tight tolerances can be achieved

The Main Reason To Choose Cnc Turning China

Over past two decades Chinese manufacturers increasing adoption of large-scale CNC Turning tools. And in doing so, China became the go-to solution for hardware companies around the globe.

China always offers the world’s most competitive manufacturing rates. And the increase in CNC Turning suppliers is helping to reduce costs further. Companies working in China for their CNC Turning are using;

- Chinese-made Turning equipment

- Western Turning equipment

- Or a combination of both

Even nearby countries such as Vietnam and Taiwan are making development in CNC. And an increase in low-wage Turning options is arising there. But Chinese companies deliver better results in CNC Turning services. This is partly due to the establishment of more Chinese CNC industries. But also because of superior supply chain and logistics procedures in the mainland.

On the other hand clients prefer internet shopping now a day. And Chinese CNC Turning services providers are adopting this mode of service. Clients can put their online machining related orders for fast working procedure.

A guide to choose the right China CNC Turning services

Referring to CNC Turning services in China is a very good step. But it may take you a while to find the best one. That is why I write in detail about some of the points below which can guide you;

1. A visit to the Turning setup:

I would recommend that you visit the factory if you do not live far away. Because some things are not satisfying available on the internet. The whole Turning setup will be in front of your eyes due to the factory visit. You will have a detailed inspection of each item in the industry. Your satisfaction level will be high by meeting the owner of the industry face to face.

Yet, you will also be able to check out the capabilities of workers and operators there. Thus you can check that either they are capable of fulfilling your task or not. But to visit the industry, first, you have to communicate with higher authorities. So that they can make proper arrangements for your visit to the industry.

But there are also some factories about which you will find full details on the internet.China PTJ Hardware is the best China CNC Turning service, provider. You can find every single detail about the capacity and services on the internet. First, you have to visit the website and take a look at their services.

Here are some of the services that they are offering;

- a. Precision CNC Turning services:Precision Turning services are not part of every setup. Because manufacturing precise parts within given tolerance is very challenging. PTJ Hardware Co. is producing precise parts with a tolerance of 0.01mm. You only have to provide your design or model and the rest of the work is up to PTJ Hardware.

- b. 6 Axis swiss turning-milling compound Turning service:The parts having a tolerance up to 0.05 mm are achievable on the mentioned Turning services. Trained staff is available to program and manufacture the precise parts.

- c. CNC grinding services:When it comes to CNC grinding services in China. The idea about high-quality finished parts came into mind. To operate CNC grinding machines the training of the staff is essential. The parts with a tolerance of 0.005 ~ 0.01mm are achievable on them. Surface finish will unmatch, even there will be no need for next finishing processes.

- d. CNC lathe Turning services:CNC lather machines are very important in any industry. The workpiece with a diameter of 500mm is achievable on CNC lathe Turning services. The achievable tolerance range is 0.01 ~ 0.02mm on these machines.

- e. CNC 6 axis high precision automatic turning-milling services:These are best to manufacture the workpiece with a diameter of 500mm. And the tolerance within a range of 0.002mm is achievable.

- f. CNC Turning services:The setup will be incomplete without CNC Turning services. These machines are the backbone of any factory. There is a need for high skilled staff to operate these machines. The workpiece with 100 x 80 x 40mm dimensions is achievable on these machines. The achievable tolerance range is 0.01 ~ 0.02mm.

- g. WEDM services:Electric discharge wire cutting machines can manufacture accurate parts. The achievable tolerance range is 0.001mm on these CNC machines.

2. First place a small order:

When you start getting services from a factory, do not place a large order first. Try to start with a small order first then go for large orders. In a way, it will be a trial for you. And you will know whether this setup has such capability or not. And in this way, you will avoid great loss in obtaining Turning services.

China Cnc Turning Parts And Case Studies

CNC turning process adopts computer numerical control program to machine round shape parts, it works with many materials plastic or metal. The advantage of CNC Turning process is the high consistent quality in terms of tolerance and smooth surface compared with traditional manual turning machines.

One thing that sets We apart is our comprehensive offering of machining services. From prototype to large production runs of machined parts, we can handle all of your project requirements from design, light assembly, to parts finishing. A few of the secondary operations include: painting, plating, precision grinding, powder coating, anodizing, annealing, heli coil installation, and more. One purchase order, one point of contact, we’ll handle it all.